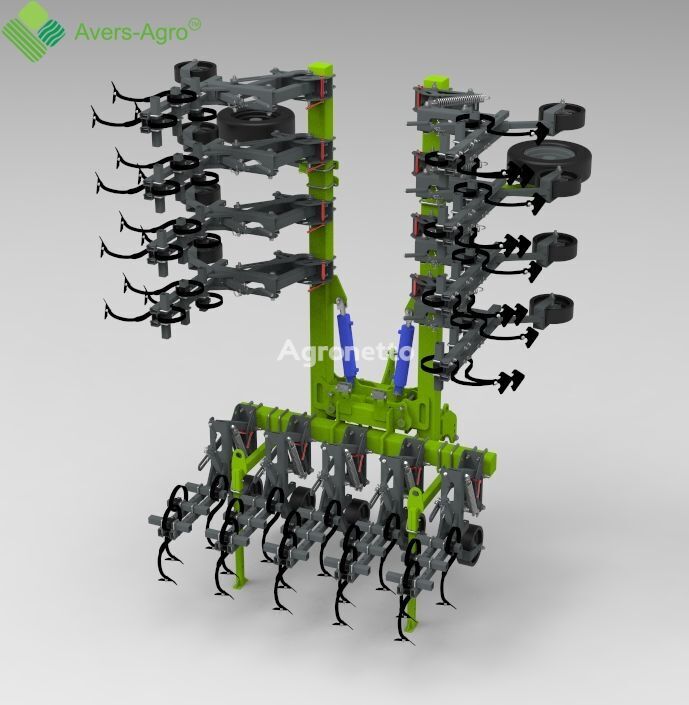

New Green Razor 5.6 m Euro cultivator

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Ukraine

Ukraine

designed for inter-row processing of any crops: cereals, row legumes, vegetables, etc.;

fights one- and perennial weeds resistant to soil herbicides;

destroys the soil crust, loosens the surface of the field, creates a mulch layer on the soil surface to retain moisture;

improves the water permeability and quality of the air regime of the soil;

activates microbiological processes in the soil;

introduces fertilizer into the soil;

zone robots light, medium, heavy soils;

it is most effective to use the tilled cultivator immediately after the rain;

the depth of processing depends on the timing, phase of development of crops and soil moisture.

Advantages and design features of the Green Razor row cultivator 5.6 m Euro:

has a high frame, which allows for inter-row processing at a later stage of the growing season;

processes crops of tilled crops with low and high stems up to 90 cm;

the method of fastening sections with working bodies makes it possible to easily adapt to different row spacing, the row spacing can be adjusted from 45 to 70 cm;

sections with the working bodies of the cultivator are equipped with universal lancet paws, mounted on a spring vibration rack;

paws and racks are made of steel of increased wear resistance, paw width 150 mm;

five working bodies are fixed on one section when adjusting for a row spacing of 600-700 mm or three working bodies when processing a row spacing of 450-500 mm;

each section with working bodies has a support wheel, which makes it possible to copy the field surface across the entire width of the unit;

a safety spring is installed on each section with working bodies, which ensures the correct clamping force and precise retention of the tillage depth;

in the design of sections with working bodies, plain bearings made of a special composite material are used that do not require maintenance;

roller bearings of support wheels are protected by anthers, which allows to extend their service life;

it is used in various soil and climatic zones when processing soils of different mechanical composition with moisture content up to 28% and hardness up to 3.5 MPa (35 kg / cm²);

the transfer of the cultivator from the working position to the transport one, and vice versa, is carried out by lowering the tractor hitch; in the parking position, the cultivator is on supports;

by design and method of aggregation mounted cultivator;

aggregation with wheeled and caterpillar tractors from 80 hp;

attendants - 1 person (tractor driver).

Additional equipment:

liquid and dry fertilizer application system;

auxiliary shields that protect the leaves of plants from damage or falling asleep with soil;

finger polyurethane wheels;

combs;

various paw combinations.

Specifications:

Operating speed, km/h ... 3-10

Working width, m ... 5.6

Productivity, ha/h ... 1.7-5.6

Max. processing depth, mm ... 120

Working bodies (for row spacing 700 mm), pcs ... 13

Minimum row spacing, mm ... 450

Maximum row spacing, mm ... 700

Paw width, mm ... 150

Transport speed, km/h … 20

Transport dimensions, m ... 2.7 x 2.2 x 3.7 ( Width x Length x Height )

Cultivator weight, kg ... 1710

Mass of a cultivator with a liquid fertilizer system, ... 1863

Tractor power, not less than hp ... 80

Type ... hinged

Service personnel, people ... 1 (tractor driver)